People who often make fabrics know that there is a proc […]

People who often make fabrics know that there is a process in fabrics called desizing, but those who have just touched the fabrics don’t know much about this desizing, so what is the use of this desizing? Why do desizing. In fact, the warp yarn is often subject to relatively large tension and friction during the weaving process of the fabric. If the fabric fiber itself is not strong, it is very easy to break, so reduce the loss of breakage, reduce the cost, and improve the quality of the fabric. It is necessary to treat the fabric before weaving, and this treatment is sizing, that is, a layer of sizing film is applied to the yarn to make the yarn tighter and smoother. This method is used to improve the strength and The abrasion resistance makes the yarn not easy to break during the production process and increases the loss.

And there are three kinds of slurries used in this process, which are divided into starch and sodium alginate in natural slurries, soluble starch and carboxymethyl cellulose in modified slurries, and polyvinyl alcohol PVA and polyacrylate PA in synthetic slurries. . Basically, the sizing materials are of these three categories.

The sizing rate also has a high or low, it is related to the quality of the fiber, yarn count, density, type of loom, generally 4% to 8%, thread fabric can not be sizing or the rate is below 1%, compact fabric (such as Poplin) sizing rate can reach 8%~14%. In recent years, the warp sizing rate of high-speed looms has exceeded 14%.

But after sizing, although the yarn strength does become higher, the sizing yarn is not suitable for subsequent scouring and bleaching processing. Therefore, desizing becomes one of the necessary procedures. The process can remove most of the slurry on the fabric, making it easier to handle in the subsequent scouring and bleaching process. At the same time, desizing can also remove some natural impurities, which is an essential basic process in the current process.

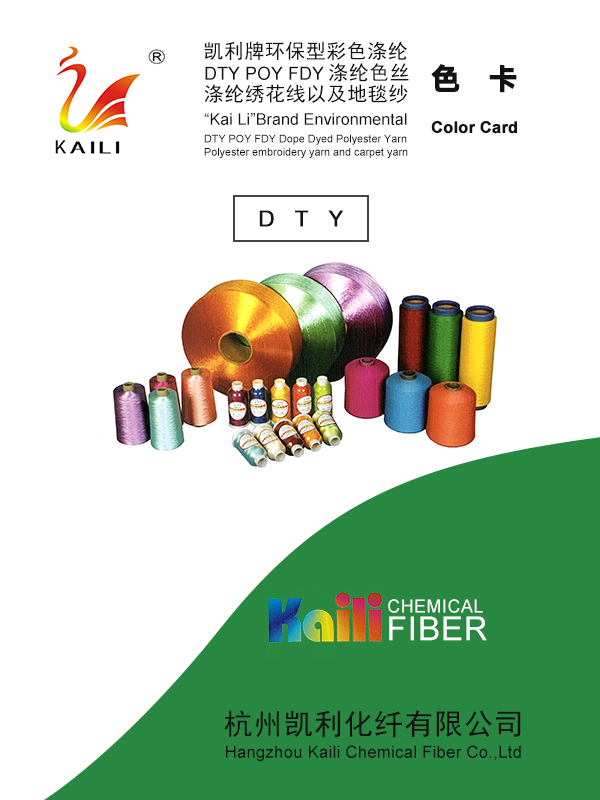

Hangzhou Kaili Chemical Fiber Co., Ltd. is functional yarn Manufacturers. The company was founded in October 2002 with registered capital of 10 million US dollars, but its total assets have reached 50 million US dollars. Enterprises with Credit, High Quality and High Quality Service .Visit klthread.com