The chemical fiber in the fabric is a type of fabric th […]

The chemical fiber in the fabric is a type of fabric that has been controversial, but it is an indispensable type of fiber, such as polyester and nylon. The functional yarn is often made because the fabric is not breathable and moisture-proof, and it is not very healthy to the human body. Those who are discouraged. Man-made fibers such as polyester seem to be a representative of low-grade unhealthy. However, the shortcomings of man-made chemical fibers are obvious, but the advantages are indelible. Such as good strength, elasticity and so on. Can not be generalized, think that adding chemical fiber is definitely worse.

So what are the types of chemical fibers for clothing? What are their characteristics.

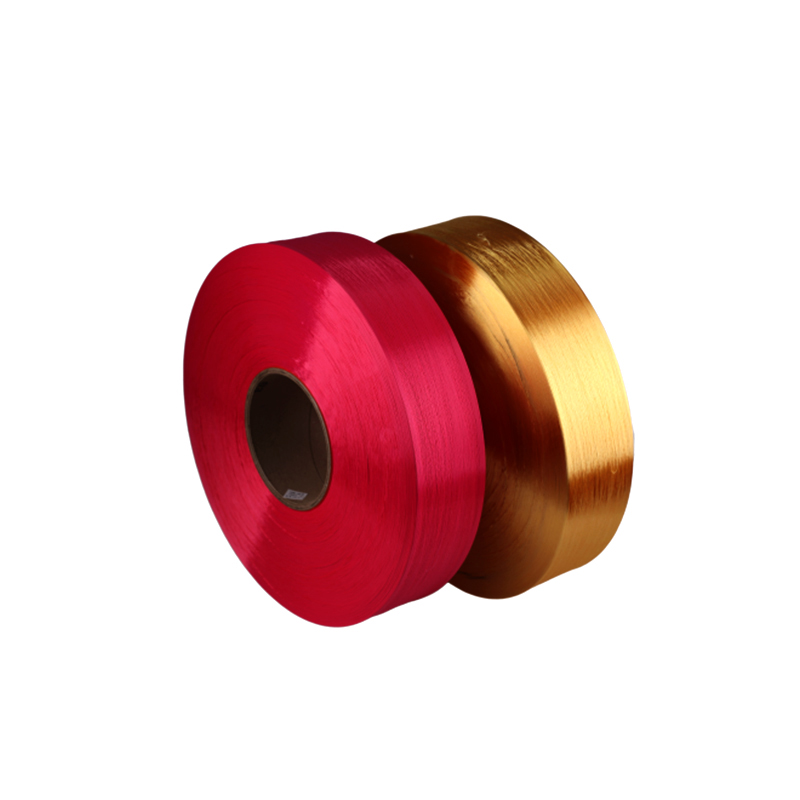

In fact, there are many chemical fibers in our lives, such as textured yarn, composite fiber yarn, special-shaped fiber yarn, superfine fiber yarn, easy-dying fiber yarn, high shrinkage fiber yarn, water-absorbent fiber yarn, mixed fiber yarn and so on. Many of the fabrics we wear in our daily life are made of chemical fibers, including high-end fabrics. For example, chemical fiber fabrics, interwoven fabrics, and interwoven elastic fabrics all use chemical fiber filaments, among which interwoven elastic fibers are excellent mid-to-high-end fabrics. For example, ordinary pongee, peach skin, chiffon, taslon, composite silk chiffon, composite silk chaotic, nylon four-sided, polyester four-sided stretch, etc. use modified fiber yarn, while cotton-nylon stretch fabrics, The chemical fiber yarns used in Tencel polyester, Tencel nylon, cotton polyester stretch fabric, interwoven nylon cotton, interwoven polyester cotton, polyester nylon cotton, etc. are differentially modified fiber yarns.

1. Textured wire

Ordinary filaments are chemical fibers that are relatively straight and easy to separate. They have a relatively dull luster, high brightness, easy to tear, and are slimy and comfortable to wear. Therefore, in order to change this shortcoming, we can improve the crimp shape of chemical fiber to change the performance. This is the origin of textured yarn, which can be heat-set to keep the fiber in a firm crimped form permanently. This can improve the gloss, feel, and comfort of ordinary filaments. A well-known example is polyester imitation silk satin made of polyester triangular shaped yarn.

2. Composite fiber yarn

This is a fiber with side-by-side, core-sheath, and sea-island cross-sections. It is a fiber made of two or more polymers through a spinneret hole. It can keep the fiber elastic for a long time and curl permanently. Moreover, this fiber is easy to dye, antistatic, and excellent in moisture absorption. The most typical is the composite silk imitation silk fabric polyester composite silk flower crepe, which is very popular in spring and summer because of its good elasticity, soft hand feeling and natural luster.

3. Shaped fiber yarn

Its fiber cross-section is unique, with a special fiber shape and hollow in the middle, which can improve the hand feel and luster, and the fabric made has a fluffy feel. The advantages of anti-pilling and fluffing are also excellent. Its typical representative is hollow cotton that keeps warm.

4. Superfine fiber yarn. Its other name is better known, which is ultra-fine denier fiber. Generally, it can be obtained by direct spinning, or dissolution removal method and peeling method. This kind of fiber has low stiffness, extremely fine hand feel, and generally good warmth retention. Due to the large surface area of the fiber, the ability to adsorb impurities and decontamination is very strong, and has a certain degree of drape. Typical superfine fiber fabrics generally include polyester superfine denier suede and peach skin.

5. Easy to dye fiber yarn

Like its name, it can be dyed with different dyes instead of high temperature dyeing. Its characteristics are that this fabric has bright color after molding, strong color fastness, uniform color tone, low probability of height difference, and complete color spectrum, and most colors can be made.

6. High shrinkage fiber yarn.

This kind of fiber can undergo regular bending and contraction and compound shrinkage in length under high temperature or humid conditions. There are many typical fabrics, such as three-dimensional graphic fabrics, jacquard fabrics, foam crepe fabrics, bulk fabrics, and high-density fabrics. The high-shrinkage fiber used is a relatively common fiber filament in the current market and a large amount of fiber.

7. Water-absorbent fiber yarn

This generally refers to fiber filaments that can easily absorb moisture and transport it to adjacent fibers, and can be used to improve fabrics with poor moisture absorption. It can generally obtain high moisture absorption by three methods, such as increasing the micropores of fiber filaments, mixing high moisture absorption polymers, and modifying the surface.

8. Mixed filament

This kind of composite yarn generally refers to a mixture of monofilaments with different morphologies and functions. After mixing, it can improve the performance of the fiber. If false twisting, parallel twisting, and airflow intertwining are used, mixed filaments can also be knitted. Because of the mixed fiber, there will be voids in the fiber, which reduces the friction between the fibers, making the mixed fiber fabric more fluffy, elastic and comfortable to wear. Excellent moisture absorption.

Even chemical fibers, but their advantages are countless, blindly looking at them with a degrading perspective is incorrect thinking, how to use them, give full play to their characteristics, and avoid shortcomings, is the subject of Hangzhou Kaili Chemical Fiber Co., Ltd.

.